The Automotive Industry Action Group (AIAG) is a unique not-for-profit organization where OEMs, suppliers, service providers, government entities, and individuals in academia have worked collaboratively for more than 38 years to drive down costs and complexity from the automotive supply chain.

AIAG has a broad portfolio of quality products, services, and events created by industry volunteers and available to all. The Production Part Approval Process (PPAP) is the industry standard that ensures engineering design and product specification requirements are met.

Lexan Cabling Solutions Inc. as an AIAG member, through the PPAP guideline, and in way to its only objective, customers satisfaction, understand the requirements of customers to obtain part approval of supplier manufactured parts. Applicable to all parts and commodities, application of these principles reduces delays and non-conformances during part approval.

Lexan’s products are used in a variety of industries, and our only objective is their satisfaction. Our ISO certification ensure that all our processes are continuously monitoring and improving toward their needs and expectation, managing to get results of highest level of customer satisfaction.

ISO 9001 helping us increase the control of our business processes, resulting by improved consistency and increasing consistency means our customers are getting the same service or same products every time they are making business with us.

ISO certification required the training and development of our staff being maintained, it provides the necessary tools for them to do their jobs such as procedures, instructions and metrics. Our employees will be more knowledgeable of what they are doing and since they will keep getting trained , their careers will improve, resulting Empowered Employees.

IPC is the global association that helps OEMs, EMS, PCB manufacturers, cable and wire harness manufacturers and electronics industry suppliers build electronics better.

We are keeping our standards high. IPC helping us to strengthen our bottom line and build more reliable, high-quality products through proven standards, certification, education and training, thought leadership, advocacy, innovative solutions and industry intelligence. We Empower our Employees to make informed decisions and achieve our business goals and objectives.

Lexan Cabling Solutions Inc. as an IPC member, through the STANDARED manufacturing guideline, and in way to its only objective, customers satisfaction, understand the requirements of customers to obtain highest level of customer satisfaction.

Statistical Process Control (SPC)

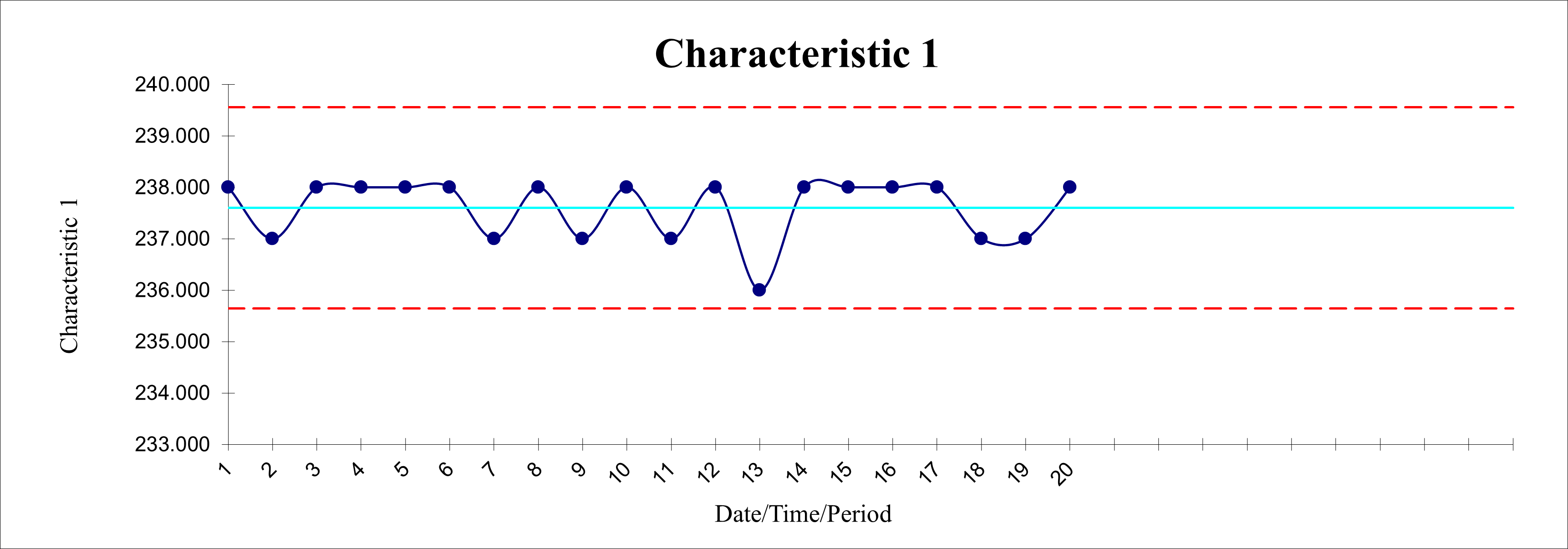

Our manufacturing are divided to several processes, and each of these processes are monitoring with our Statistical Process Control (SPC) methodology that including regular data collection intended to keep the process in a “state of control”. Quality data is collected in the form of product or process measurements or readings from various machines or instrumentation. The data is collected and used to evaluate, monitor and control a process. SPC is an effective method to drive continuous improvement.

By monitoring and controlling a process, we can assure that it operates at its fullest potential.

And by monitoring the performance of a process in real time the operator can detect trends or changes in the process before they result in non-conforming product and scrap.

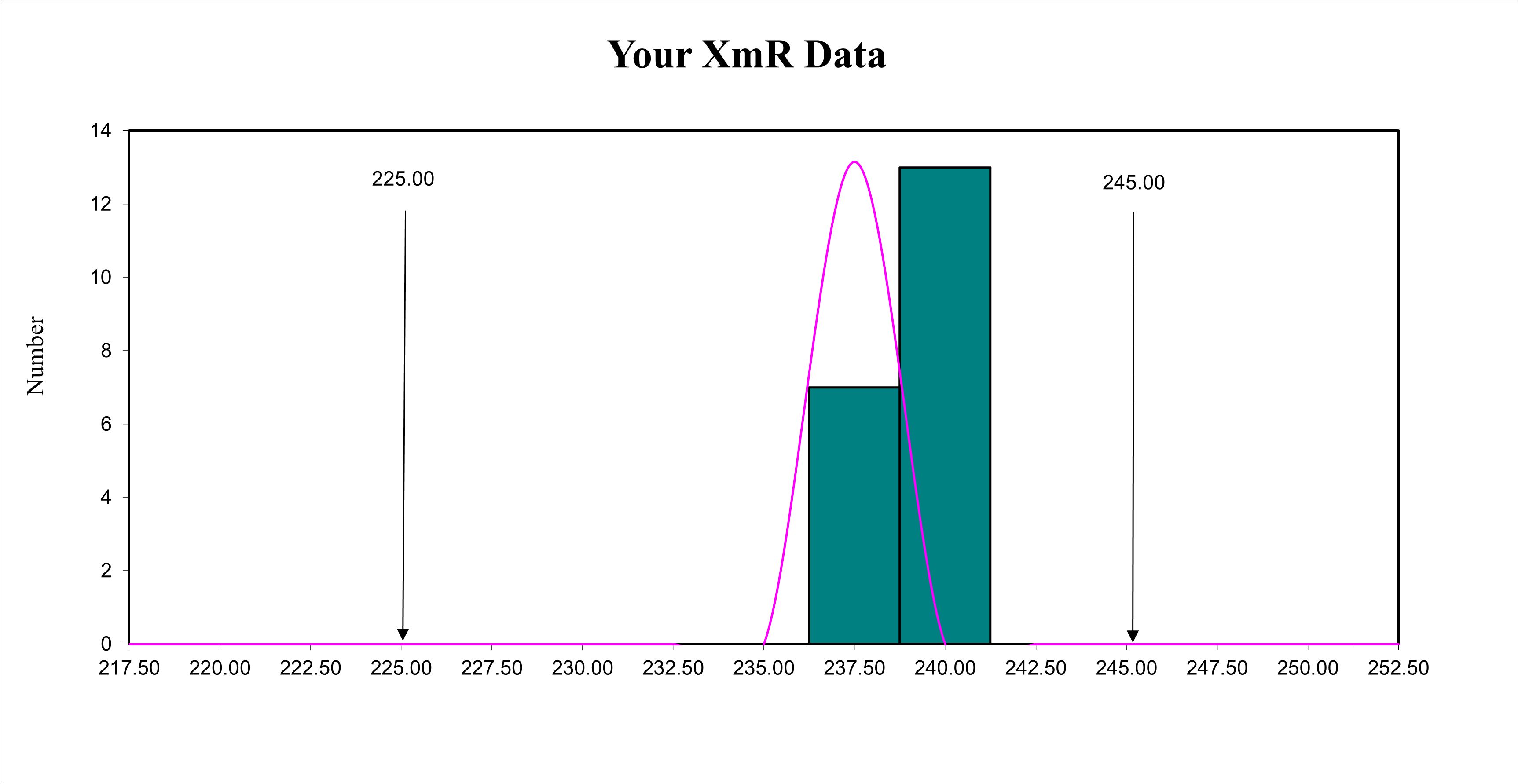

Capability analysis

The output of the statistical process control(spc) is expected to meet customer requirements, specifications, or engineering tolerances. Engineers conduct a process capability study to determine the extent to which the process can meet these expectations.